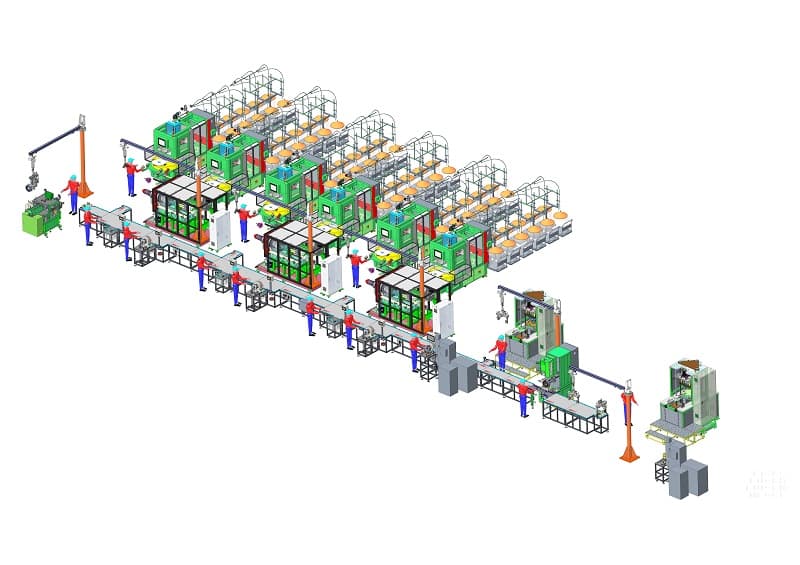

EV Traction Motor - Full Line

| Power Range | 165 HP |

|---|---|

| Operators | 20 (Machine:10 /Wiring:10) |

| Productivity | 80 pcs (8 hr. & 90% Activity) |

| Model Change | <30 min. (6 opt.) |

F Client is a leading brand in Taiwan specializing in the research, design, and manufacturing of industrial motors. In recent years, they have expanded into the development and production of EV motors and EV Powertrain systems, supplying renowned global EV manufacturers with related power systems.

This project marks F's first automotive EV motor production line using automated equipment. The production line consists of slot paper insertion machines, vertical winding machines, coil insertion and inter-phase forming machines, pre-lacing forming machines, lacing machines, final forming machines, wire connection workstations, non-power flow lines, and customized stator carriers, etc.

After the commencement of mass production, F informed us that, with the same specifications, their skilled manual coil insertion technicians previously took 8 hours to complete the production of one stator. However, with this production line, they achieve a remarkable production speed of one stator every 360 seconds, resulting in an average productivity increase of over 4 times.