Single-Phase Surface Pump

| Power Range | 0.25hp~1hp Stator |

|---|---|

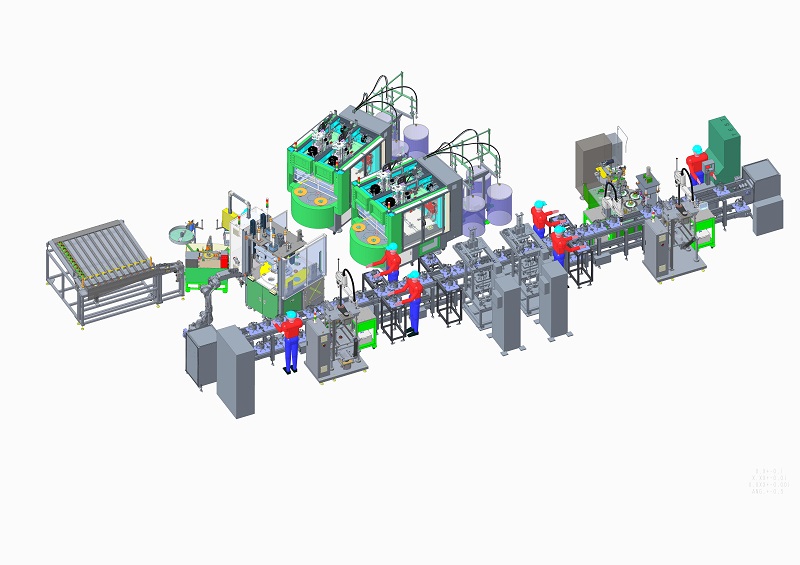

| Operators | 10 (Machine:3 /Wiring:7) |

| Productivity | 800~1100 pcs (10 hr. & 90% Activity) |

| Model Change | <30 min. (2 opt.) |

All specifications and designs are subject to change without notice.

W Customer is a leading surface pump manufacturing brand, specializing in the production of high-quality water pumps. While W Customer's existing stator supply met the required standards, their production capacity was limited. In order to enter the international market, W Customer has made the decision to invest in an automated production line for motor stators, aiming to fulfill a high volume of international orders in the future.

To address the future shortage of labor, the production line incorporates a stationary automated assembly line and four robotic arms. The line also utilizes dual-head automatic winding machines to improve efficiency and quality of the winding process. Additionally, a turntable coil insertion machine is employed to enhance material feeding efficiency, aligning with the daily production capacity plan. Furthermore, the introduction of automated welding machines has overcome the limitations of manual wire welding, ensuring stable welding quality. These technologies will enhance production efficiency and ensure product quality.

The implementation of an automated stator production line by W Customer is driven by the company's future development and market strategy. This investment has increased in-house production capabilities, improved delivery flexibility, and enhanced the company's competitiveness.