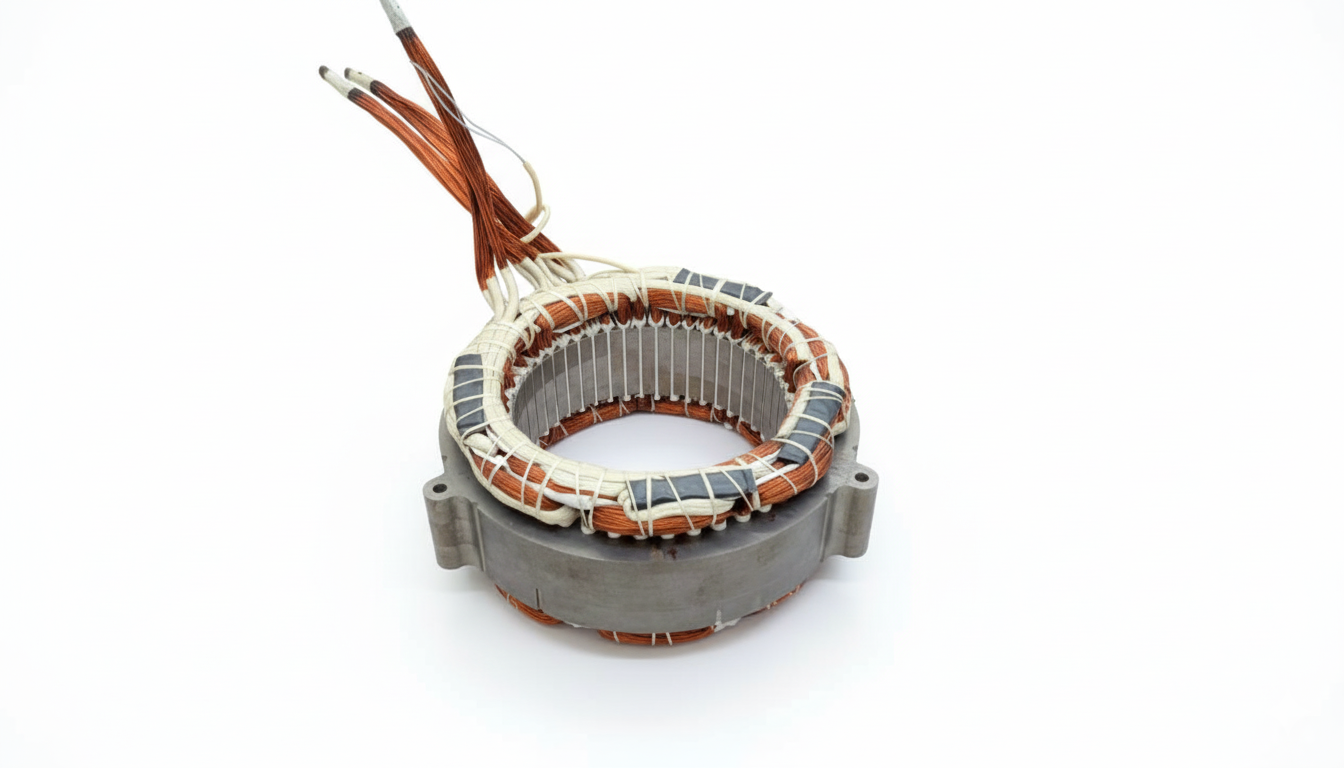

GMW Motor Prototype:

Optimize R&D for High-Performance & Precision Motors

In the competitive high-tech markets of the US and Australia, achieving rapid Time to Market Reduction is essential. GMW's Motor Prototype Service platform accelerates design validation for EV Motor, Drone Motor, and Robotics Servo Motor R&D teams, ensuring seamless transition to mass production.

→I. How GMW Accelerates Your EV Motor and Drone Motor R&D

The global electric motor market is projected to reach $258.17 billion by 2032 (7.52% CAGR). To capitalize on this growth, R&D teams often face delays due to the high barrier of entry for specialized Motor Winding equipment and long prototype cycles.

The GMW Motor Prototype Service mitigates these risks, delivering significant Time to Market Reduction, particularly for high-power-density EV Motor and Drone Motor applications in Western markets.

Global Electric Motor Market Forecast (CAGR 7.52%)

Data Source: Fortune Business Insights

2. R&D Team Challenges: The Three Major Pitfalls of Traditional Motor Prototyping – Slow, Expensive, and Lengthy

Traditional sample development often requires companies to build their own winding equipment and invest in molds and jigs. This process is not only time-consuming but may also lead to inconsistencies between prototype and mass production conditions, affecting subsequent validation and performance.

Traditional Manual Winding vs. GMW Automated Winding Advantages

Traditional Manual Winding

Quality is inconsistent, highly dependent on operator experience, which may lead to weak insulation points and reduced motor lifespan.

GMW Automated Winding

Program-controlled precision ensures higher slot fill rates and improved motor efficiency.

Traditional Manual Winding

Low efficiency with long prototyping cycles, heavily dependent on labor hours, lacking scalability benefits.

GMW Automated Winding

High-efficiency continuous production reduces prototyping from days to hours, significantly accelerating product development.

Traditional Manual Winding

Although initial investment is low, long-term hidden costs from low yield, labor, and training can be substantial.

GMW Automated Winding

Higher initial investment, but high yield and efficiency allow ROI within 18 months, demonstrating significant cost-effectiveness.

Traditional Manual Winding

Lack of data recording makes it difficult to track process parameters accurately, complicating product issue tracing.

GMW Automated Winding

Equipment with PLC interface precisely records all winding parameters, provides complete data traceability, and has built-in inspection functions.

III. The GMW Edge: Motor Winding Experts for Seamless Transition

Leveraging extensive experience in Motor Winding equipment manufacturing, the GMW Motor Prototype Service ensures that mass-production readiness is considered from the earliest design stage. This preempts costly delays caused by insufficient Design for Manufacturability (DFM), enabling true Time to Market Reduction.

- Zero-CapEx Start-Up: Focus on design; we handle the sample production without requiring your capital investment in specialized Motor Winding machinery.

- Mass-Production Grade Validation: Our facility features a diverse range of immediate-to-use winding machines, ready to produce your stator samples.

- Minimized Risk: Prototype stability and quality directly align with mass-production standards, minimizing risk for your EV Motor and Robotics Servo Motor projects.

- Accelerated Schedule: Avoid the time and expense of secondary validation. Overall project timelines can be shortened by weeks or months.

IV. The Bridge from Design to Manufacturing: Critical DFM Verification

Design for Manufacturability (DFM) Verification is the insurance policy that secures high success rates for your EV Motor and Robotics Servo Motor projects, mitigating future mass-production risks.

In motor winding design, pre-validating the following parameters is critical:

- Wire diameter vs. slot width ratio, winding density, and achievable slot fill rate (High Slot Fill Winding).

- Coil end-turn shape, interference checks, and feasibility of automated insertion.

For high-cost applications like EV Motor and Drone Motor, optimizing Motor Winding efficiency and slot fill is the core strategy for maximizing BLDC motor performance and reducing overall material cost.

🤝 Case Studies: High-End EV Traction and Robotics Joint Modules

Case I: EV Power Train Project — High Slot Fill Traction Motor Line

Project & Client

- Collaboration: Partnered with an EV Power Train manufacturer focused on international markets.

- End Application: High-performance traction motors for new-generation electric vehicles.

- Project Scope: Developing a full automated winding line for EV traction motor stators.

Core Technology & Line Composition

- Stator Specs: ID 200 mm, OD 300 mm, 3-phase winding.

- Technical Challenge: Achieved an industry-leading **Square Wire Slot Fill Factor of 86%** in mass production.

- Line Components: Included insulation paper insertion, straight-drop winding machine, wire insertion & phase forming unit, coil forming, and lacing machine.

- Integration: Heavy-duty stator handling fixtures and optimized workflow.

Status: The production line is operational and validates GMW’s leadership in high-end, heavy-duty EV traction motor processes.

Case II: Robotics Application — Joint Module Development

Project & Client

- Target Field: High-precision servo motors for advanced robotics joint modules (e.g., robotic dogs).

- Requirement: Extreme accuracy, high power density, and stability.

GMW Contribution

- Assistance: Developed critical motor samples and optimized the process using high-precision automatic winding equipment.

- Core Value: Provided DFM consultation to shorten the validation cycle for high-performance servo modules.

V. Key Application Areas: EV Motor, Robotics Servo Motor, and Drone Motor

GMW's Motor Prototype Service is critical for next-generation powertrain and intelligent systems, transforming your design concepts into verifiable product advantages.

Electric Vehicles (EV Motor / Hub Motors)

Motor Requirements: High efficiency, high torque, long range. Optimized Motor Winding solutions.

- Test high slot fill/low-loss winding.

- Maximize range and torque.

- Samples meet stringent EV Motor standards.

Robotics / AGVs (Robotics Servo Motor)

Motor Requirements: Precise control, high stability, rapid response. Time to Market Reduction focus.

- Produce highly accurate wire alignment.

- Ensure stable, reliable samples.

- Ideal for Robotics Servo Motor structural validation.

UAV / Drones (Drone Motor)

Motor Requirements: High RPM, high power density, compact size. Critical Motor Winding DFM.

- Validate high-power-density designs.

- Rapidly acquire and iterate performance data.

- Accelerate Time to Market Reduction for miniaturized applications.

VI. GMW Prototype Process: Ensuring Time to Market Reduction

Our streamlined process ensures you receive mass-production-ready samples quickly, accelerating your EV Motor and Robotics Servo Motor development timeline.

Submit Design Specs

Client provides motor drawings

→Free Feasibility Review (DFM)

GMW DFM assessment & Quotation

→Prototype Motor Winding

Production on GMW mass-grade equipment

→Sample Delivery & Test

Client validates EV Motor or Drone Motor performance

→Mass Production Start

Seamless transition with GMW's proven process

Start Your Time to Market Reduction Journey Today

Don't let Motor Winding complexities delay your EV Motor, Drone Motor, or Robotics Servo Motor launch. Partner with GMW for validated, mass-production-ready prototypes.

Contact GMW for a Free DFM ConsultationVII. Frequently Asked Questions (FAQ)

Which industries benefit most from GMW's Motor Prototype Service?

- Manufacturers of Electric Vehicle (EV Motor) systems.

- Developers of high-precision Robotics Servo Motor joint modules.

- Producers of industrial/commercial UAVs (Drone Motor), particularly in the US and Australian markets.